The quality and types of water are defined through a series of measurements of Total Organic Carbon (TOC) in parts per billion (ppb), conductivity (µS/cm) or resistivity MΩ-cm), and bacterial count (CFU/ml).

Table of Contents

ToggleWater (H2O) is an inorganic, transparent, tasteless, odorless, and nearly colorless chemical substance, which is the main constituent of Earth’s hydrosphere and the fluids of all known living organisms (in which it acts as a solvent).

It is vital for all known forms of life, despite providing neither food, energy, nor organic micronutrients. Its chemical formula, H2O, indicates that each of its molecules contains one oxygen and two hydrogen atoms, connected by covalent bonds.

The hydrogen atoms are attached to the oxygen atom at an angle of 104.45°. “Water” is also the name of the liquid state of H2O at standard temperature and pressure.

In the water purification industry, there are four levels of water purity recognized, each of which is used for specific applications in laboratories.

Here we explained the four types of water used in laboratories, as well as the properties and processes of each type.

Types of Laboratory Water

1. Ultrapure Type of Water (Type 1)

For the requirement of analytical laboratories, water with a conductivity resistance of 18.2 MΩ-cm at 25°C is used. Specifically, pyrogen-sensitive applications, Flow cytometry, cell, and tissue culture applications, Type 1 water, or ultrapure water are used.

Water with this type of resistivity can still contain organic contaminants, endotoxins, and nucleases which don’t impact resistivity values, so further other technologies are used to eliminate them.

The water flows through a vessel containing a dual wavelength of ultraviolet (UV) light (185nm and 254nm), which damaged any genetic materials present in the water which are required for the reproduction of microorganisms.

This prevents the microorganisms from multiplications or replications and eliminates the microorganisms.

At the end of the system, an ultrafilter (UF) is also used to produce DNase/RNase-free water to ensure the near-total removal of macromolecular impurities.

By using size exclusion, ultrafiltration removes particles and macromolecules and is sometimes charged to attract contaminants.

You May Also Read: Nanotechnology Products in Daily Life

2. General Laboratory Grade Type of Water (Type 2)

This type of water is also known as general laboratory-grade water. Type 2 water is produced through a combination of reverse osmosis, and additional technology such as ion exchange or electrical ion exchange (EDI).

Moreover, EDI is an active purification technology that combines electrodialysis with ion exchange. Water is passed between an anion-permeable membrane and a cation-permeable membrane within an EDI cell.

The cell chamber contains loosely packed ion exchange resin. Ions are then attracted to the oppositely charged electrode, but they’ve flushed away before they’re able to reach it, which means they’re removed from the water.

Deionisation, or ion exchange, removes ions from RO water by using synthetic resins. Chemical reactions occur as the water passes through the ion exchange beads, resulting in the removal of ions.

This process is continued until all unwanted ions are replaced by hydrogen and hydroxyl ions, which form pure water once combined.

Together, these two processes produced resistance to the conductivity of 1-15MΩ-cm and make it suitable for general applications such as general chemistry, spectrophotometry, media, and buffer production.

3. Primary Grade Type of Water (Type 3)

This type of water (Type-3 water) uses carbon filtration and reverse osmosis (RO) technology, which is the most cost-effective way to reduce water contaminants.

In RO, water flows from a less concentrated solution through a semipermeable membrane to a more concentrated solution.

Further, by applying external pressure to the more concentrated side, the osmotic flow is reversed, which forces the water through the membrane, and deposits the impurities on the surface.

RO technology applies diffusion as opposed to separation, rejecting particles with a higher molecular weight.

Feed water temperature, pressure, and the physical condition of the RO membrane are all parameters that affect rejection rates.

Therefore, whilst rejection rates are variable, they tend to increase as the ionic charge and size of the molecule increase. For this reason, RO water can’t be specifically classified.

RO water is most commonly used at the starting point for many applications in laboratories, including feeding glassware washing machines, and autoclaves.

It can also be used as a pre-treatment for ultrapure water systems, or anything that’s considered non-critical.

4. Feed Water

Feed water is also referred to as potable or raw water, and its quality of it is dependent on its source.

Whilst deep water is naturally filtered by layers of rock and soil, water from surface sources like lakes and reservoirs is at risk of environmental contamination.

Raw or feed water is typically identified by measuring its odour, color, and turbidity. The chemical characteristics such as pH, hardness, and bacterial contamination of this type of water vary greatly.

Some of the most significant contaminants of feed water include dissolved ions, minerals, microorganisms, and organic compounds.

Feed water should always be tested, and have appropriate pre-treatment measures conducted, to ensure that the quality is sufficient enough to not damage the downstream purification technology.

You may also read: Nano Curcumin and its hidden potentials

The most common type of pre-treatment is depth filters. In this process, the raw water passes through a series of winding fibers, which attract and trap impurities.

Carbon is also used to bind chlorine ions because if they’re not removed, they will cause rapid deterioration of reverse osmosis (RO) membranes.

Another step commonly taken is the installation of a water softener, reducing the hardness level of water before it reaches the RO membrane; hard water causes scaling of the RO membrane and reduces its lifespan.

To achieve a certain standard of purity, each type of water must go through various processes and technologies. According to the level of purity, they can be used in laboratories for different purposes.

Therefore, it’s important to be able to distinguish between the four types of water.

You May Also Read:

- Beware of Post-COVID Complications due to COVID-19!

- Avascular Necrosis due to COVID-19 may cause severe problems!

- Alzheimer’s Disease – Causes and Consequences

Milli-Q water

Milli–Q is a trademark of Millipore Corporation company to describe “Type 1 water or ultrapure water” i.e. filtrated and deionized. Milli-Q water is produced by the reverse osmosis (RO) water purification process.

In the reverse osmosis process, a partially permeable membrane is used to separate larger particles, unwanted molecules, and ions.

Moreover, an applied pressure is used to overcome osmotic pressure, minimum pressure needs to be applied to a solution to prevent the inward flow of its pure solvent across a semipermeable membrane.

Through this process, many types of dissolved impurities such as chemical species, biological entities (bacteria, viruses, enzymes, etc.), dust particles, and ions are removed from the water and are used for both industrial and research purposes.

Milli-Q water is water that has been purified using a special ion exchange cartridge, which increases its purity, and the purity of water is assessed by measuring the resistance of the water to conduct electricity.

As the resistance of the water to conductivity increases, indicating fewer ions in water and the purity of water increases.

A value greater than 18.2 MΩ cm-1 (@ 25 °C) is desirable. As a final step, the water is dispensed through a 0.22 μm membrane filter, which should pull out any intact organisms, and sometimes there is a UV irradiator is attached which makes the water contamination free.

Milli-Q is a brand name, there are other brands that perform as well as the Milli-Q system. Milli-Q Water is simply water purified using a Millipore Milli-Q lab water system.

Over the past 30 years, there have been several different Milli-Q water systems and each can have up to 4 different configurations, instead of calling for Type 1 water or some other water specification, they simply called it based on the equipment available in the lab.

The basic Milli-Q produced water meeting NCCLS, CAP, or ATSM Type I water, having 18.2 megohms ionic purity with little if any bacteria.

Other versions can also give ultra-low total organic contamination (UV) and Pyrogen free water (UF)or a combination of all of the above (UV/UF).

You will also find the same thing called “Nanopure Water” or “DI Water” but all of these terms are vague when discussing the actual water quality needed for a given procedure.

Here we have put a video available on YouTube by WNP Shopper, you can check it.

pH of Mili-Q Water

The pH of Milli-Q® water is equal to 6.998.

However, as Milli-Q® water is very pure, it contains very few ions and has a low buffering capacity. Once the water has been sourced from the system, its pH value can therefore change quickly.

Any impurity on the wall of the container used to collect the Milli-Q® water will dissolve and change the pH value. Carbon dioxide naturally present in the air will dissolve in the water, producing bicarbonate and decreasing the pH value.

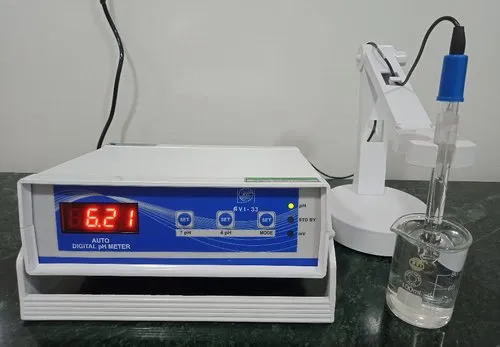

In addition, regular pH meters available in most laboratories have not been designed to operate in a solution containing almost no ions.

They are not adapted to measure the pH of Milli-Q® water and may therefore deliver inaccurate results.

Some pH meter suppliers provide documents explaining the technical reasons why conventional pH meters do not provide accurate results when measuring the pH of ultrapure water.

Some companies have designed pH meters able to measure the pH of ultrapure water in dynamic operating conditions, but these are rarely used in regular research laboratories.

This is the reason why scientific forums regularly report Milli-Q® water pH measurements far above 7.0, even though the pH of Milli-Q® water leaving the purification system is actually very close to 7.

Distilled water

Whereas, in the case of distilled water, produced by a continuous distillation process (2-3 times) of water i.e boiling and then condensation of the water. So, double distilled water has gone through the process of distillation twice.

The problem with it is that since it is continuous distillation, some contamination will come across with the water.

Water Used for Injection

Water for Injection is sterile water that contains no antimicrobial agent, bacteria, or added buffer.

It is supplied only in single-dose containers, indicated only for diluting or dissolving drugs for intravenous, intramuscular, or subcutaneous injection.

Water for injection is administered as an injection by a healthcare professional. Kindly do not self-administer. There are no common side effects seen with this medicine.

Benefits of water for injection

In Preservative

Water for Injection is used as a preservative to prevent damage to the original form of the medicine that is given as an injection by a doctor or nurse.

If it is not present, harmful organisms can contaminate the solution and cause infections or reactions in the person who takes any such medicine.

It also acts as a solvent for certain medicines and helps in better absorption of the medicine in our body.

ELIX Water

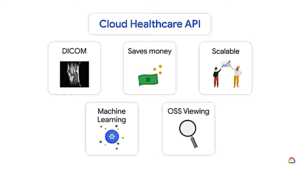

Elix® Essential delivers Type 2 pure water to support a broad range of research areas. It is designed to be fed from potable water and is the ideal feed for laboratory equipment, including ultrapure water systems.

In the Elix® Essential system′s water purification sequence, potable tap water is first treated with a Progard® pretreatment pack, followed by reverse osmosis (RO) to produce RO Type 3 water.

This water enters the Elix® electrodeionization (EDI) module, which continuously regenerates ion-exchange resins using a small electrical field.

This process requires only very small amounts of water and energy and results in consistently high-quality pure Type 2 water without a need for external chemical regeneration of the resin beads.

The pure water stored in the polyethylene (PE) reservoir can be either sourced through the tank front valve or sent by a distribution pump to feed laboratory instruments.

Use of Elix water

Type 2 pure water is one of the most widely used reagents in the laboratory. It is used by scientists, researchers, and engineers everywhere in environments as diverse as academic, hospital, and quality control laboratories.

It is used as feed to laboratory equipment (e.g., Milli-Q® Type 1 ultrapure water systems, weathering testing chambers, autoclaves, glassware washers, and dissolution testing units).

It is also used in the lab to prepare microbiological media, buffers and pH solutions, and solutions for use in histology. Examples of uses include thermodynamic studies, emulsions, and membrane science.

You may also read: Nanoplastia hair treatment is far better than keratin treatment